Nissan to adopt Giga Casting for making Electric Vehicles affordable

Nissan is set to adopt giga casting, a production technique pioneered by Tesla, to reduce electric vehicle (EV) costs and make them more affordable.

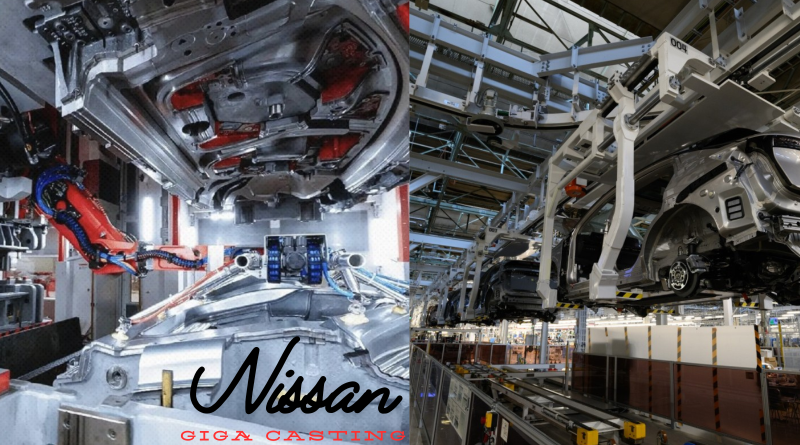

Giga casting involves casting large sections of a vehicle’s structure as single pieces rather than assembling multiple smaller parts, which simplifies production, reduces weight, and lowers costs. Nissan plans to implement giga casting by 2027, aiming to cut EV parts costs by 10% and reduce vehicle weight by 20%. This approach is expected to lead to a 30% overall cost reduction, saving about $1 billion in development costs for five future models. Tesla, which uses giga casting for its Model Y and Cyber-truck, has set a precedent that Nissan aims to follow with its 6,000-ton presses for forming the rear underbody of future EVs.

Despite the benefits, giga casting poses challenges, such as the high initial investment in large, complex machinery and the difficulty of integrating aluminum modules with steel parts. Nissan plans to address these issues using innovative fastening methods like self-piercing rivets and drill screw technologies. Nissan’s strategy aligns with a broader industry trend, with automakers like Toyota, Hyundai, and Ford also exploring giga casting. Nissan aims for 40% of its overall sales to come from fully battery-powered cars by 2031. This goal includes the launch of the next-generation Leaf in 2025 and two new EV sedans showcased at the Beijing Auto Show. By embracing giga casting, Nissan hopes to make EVs more accessible and promote their widespread adoption.